As part of an ongoing commitment to showcasing sustainable initiatives, Dandenong Market, and City of Greater Dandenong, recently commissioned a series of visual installations using recycled or re-used timber. Last Christmas, the market displayed a series of decorations made from pallets – including Christmas trees and stars. As Dandenong Market’s Marketing Manager Amanda Bevan told the Herald Sun, the market does “a lot behind the scenes to improve sustainability such as breaking down green waste, collecting rainwater and using cross-flow ventilation.”

As a follow-up to that project, Dandenong Market approached Urban Edge Landscape Architects to design a new installation. Commercial Systems Australia (CSA) were tasked with install duties, with CSA’s Product Design Engineer Craig Artemiou in turn enlisting Plain Pallets as manufacturers.

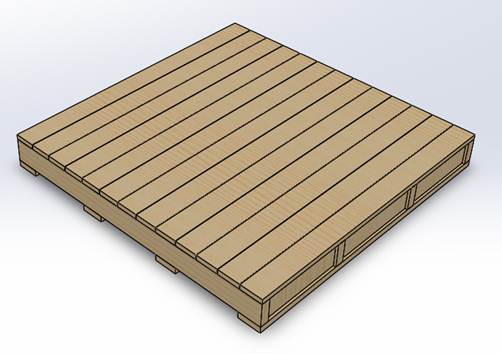

Craig’s brief for us was a little unorthodox – CSA wanted to explore manufacturing pallets in dressed kiln-dried material, which is furniture grade/building material:

14x Decking Custom Pallets (12 for the deck 2 for the table top). Dressed or rough sawn top.

- The top boards will need to be at least 20mm thick, with small gaps around 2mm.

- The open ends will need to be filled in as to not collect rubbish.

- The pallet will take lots of walking traffic and will need 4 support ribs.

6x Table Support Pallets, treated pine with a finish raw (a more standard pallet).

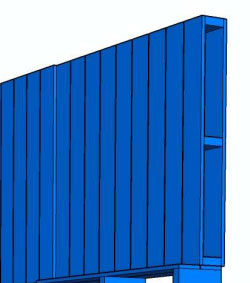

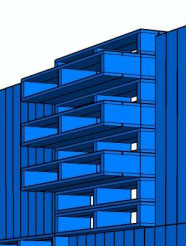

13x pallets for wall mounting, treated pine painted blue (a more standard pallet).

5x Custom Pallets made in sections wall mounted, treated pine painted blue.

8x stools. Hardwood timber, raw finish. Approx. 450mm cube.

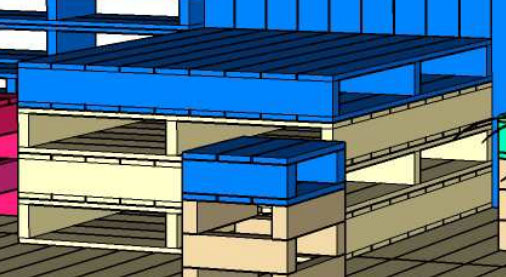

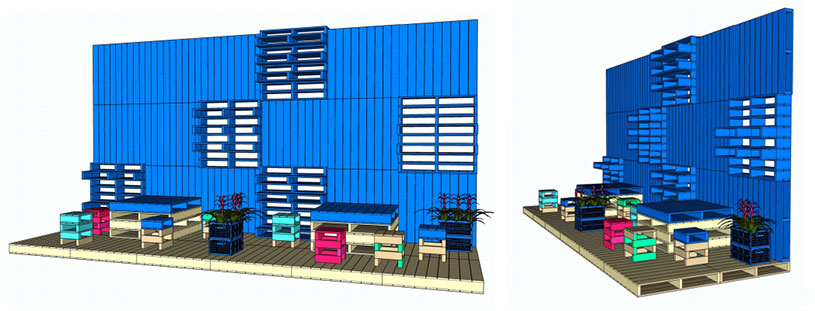

Installation design – artist’s Impression only:

As tough as our pallets are, they’re not designed to hold up buildings; they’re made in “case” grade, which usually comes from sub-building-standard timber. Manufacturing building-grade pallets made for a tricky process because everything had to be nailed even more carefully and precisely than usual. We also had only about seven to eight days to complete the job, so the time constraint presented an additional challenge.

Plain Pallets delivered the final products to CSA who then took care of the installation, with fantastic-looking results:

The project was well received by the market and the local council. We are currently waiting on further direction and to see if they choose to roll out the project to a larger area. Fingers crossed!

The project was well received by the market and the local council. We are currently waiting on further direction and to see if they choose to roll out the project to a larger area. Fingers crossed!

Must Read

Plain Pallets on 29 April 2014

How to Get Greater Mileage out of Your Pallets

Do your pallets go the distance? If not, you may be losing money through replacement costs and damaged goods. Get the most out of your pallets ...

Read morePlain Pallets on 11 March 2014

Plain Pallets Display the Future of Sustainability

Pallets are always useful. See the many ways old pallets can be reused. Who knows, maybe your next house or business will have some great pallet furniture! ...

Read more